Timber Decking

Wood Campus Timber Trade Topics are produced in collaboration with Timber Development UK and our industry experts, in this case, the Timber Decking and Cladding Association. For further information, visit www.tdca.org.uk.

TOPIC CHECKLIST

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

-

Check whether the deck needs planning permission.

-

Is the timber strong enough for the job?

-

Is it treated to the right Use Class?

-

Does the deck need a balustrade?

-

Have you checked the spans?

-

Is there a danger of slipping on the deck or steps?

-

Have you mixed metal fasteners?

Do I need planning permission?

It is the property owner’s responsibility to check whether planning or building consent is required before work starts. Contact your local Planning Department if:

- The proposed deck platform is more than 30cm (1’) above ground level

- The area of the proposed deck, together with any extensions or outbuildings, will be more than 50% of the garden

- The deck is within 20 metres’ direct line of site of a highway

- The deck will be in a conservation area, National Park, or attached to a listed building

For more information in England visit www.planningportal.co.uk. Contact your local authority for details of requirements for Scotland, Wales and Northern Ireland.

As decks are load-bearing structures, it’s vital that correct design practices, due care, materials and installation techniques are used.

Building control consent

As a general rule, any deck that requires planning permission will also require detailed construction drawings to establish that it is safe and fit for purpose. Check with your local authority.

Quality assurance

For assurance of quality, look for components manufactured under the DeckMark® quality accreditation scheme for decking.

There are four basic types of deck:

- Ground level – built directly onto the ground

- Floating – raised less than 60cm (24”)

- High level – raised more than 60cm (24”)

- Roof top – an area on an existing flat roof

The complexity of build depends on the site and height from the ground.

Timber decks can be attached to a property or freestanding.

For new properties, the National House-Building Council (NHBC) requires all decks to conform to Timber Decking and Cladding Association (TDCA) guidelines.

The information in this Timber Trade Topic is based on those guidelines.

The right timber for the job

Use timber capable of giving a service life of at least 15 years. This means either a naturally durable species, such as Ipe, Iroko, Oak, Jarrah, Balau and Western Red Cedar, or a softwood that has been pressure-treated to the right level for the job.

Check the Treated Wood Use Class table to make sure you’re buying the right timber for the job:

- Use Class 4 treated wood for structural members and items in permanent ground contact

- For the boards and railings, use Use Class 3u

Certified timber

Chain of Custody certified hardwoods and softwoods are now widely available and designers should ensure that the materials they specify can be supplied from sustainable and managed forests.

| USE CLASS | APPLICATION | RISK OF FAILURE | SUITABLE FOR DECKING |

|---|---|---|---|

| 2 | Above ground, covered, occasional risk of wetting | Low | No |

| 3u (uncoated) | Above ground, exterior uncoated, exposed to frequent wetting | Medium/High | Yes – for deck boards and non-structural timbers above ground |

| 4 | In ground contact or fresh water permanently exposed to wetting and/or providing exterior structural support | High | Yes – Decking posts, joists and sub-structures |

Timber strength

All decks should be built with strength-graded timber. Strength class C16 is considered the minimum standard, with C24 recommended for heavy domestic or commercial structures. For hardwoods, C30 is the minimum strength class.

Good quality pressure-treated softwoods with a medium or high density rating will give good wear resistance not only for private and domestic decks, but for most commercial projects as well. Species with lower density ratings, like Western Red Cedar, are more appropriate to domestic deck structures.

Slip resistance and standing water

Anti-slip decking boards, with grip inserts, are often used to give extra security. Occasional stiff brushing will reduce slipperiness.

Prevent standing water and saturated wood by designing a slight fall into the deck surface. Grooved boards, which channel water flow, can improve drainage further. Lay them so the channels are in the direction of the fall. Specifying a water repellent treatment will also help.

Metal fixings

Corrosion is the biggest threat to fixings used out of doors. Stainless steel, hot dipped galvanised, or high quality coated carbon steel fixings are best. Electroplated, brass, or uncoated steel fixings should not be used. Do not use aluminium either.

Always use the same type of metal for fixings and connectors.

| SPECIES | DENSITY RATING |

|---|---|

| Western Red Cedar | 390kg/m3 |

| British pine/E.Redwood | 510kg/m3 |

| Douglas Fir | 530kg/m3 |

| Larch | 550kg/m3 |

| Southern Yellow Pine | 590kg/m3 |

| Iroko | 660kg/m3 |

| Oak (European) | 720kg/m3 |

| Opepe | 750kg/m3 |

| Jarrah | 820kg/m3 |

| Yellow Balau | 980kg/m3 |

DENSITY RATINGS OF SOME COMMON SPECIES USED FOR DECKING

Site preparation

Clear all vegetation from under low level decks. If the area under the deck is visible, lay weed-suppressing sheeting, held in place with clips or a layer of gravel.

Construction principles

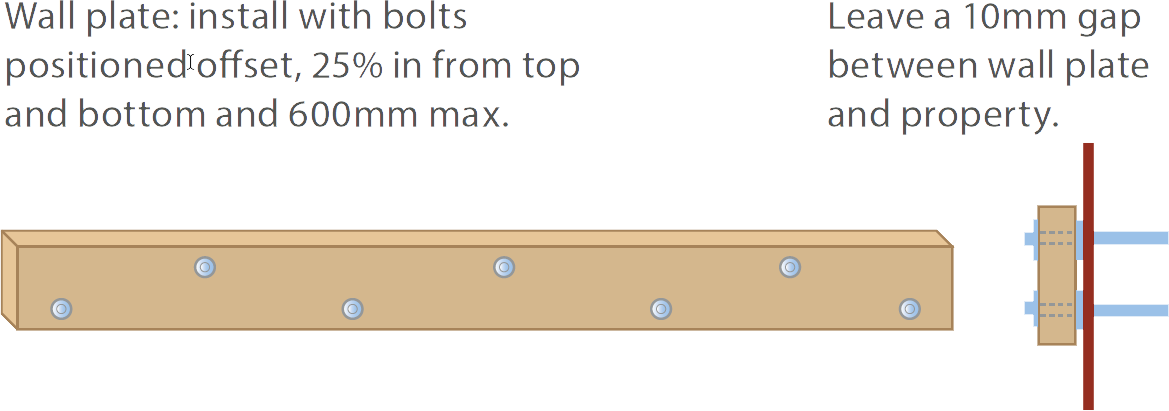

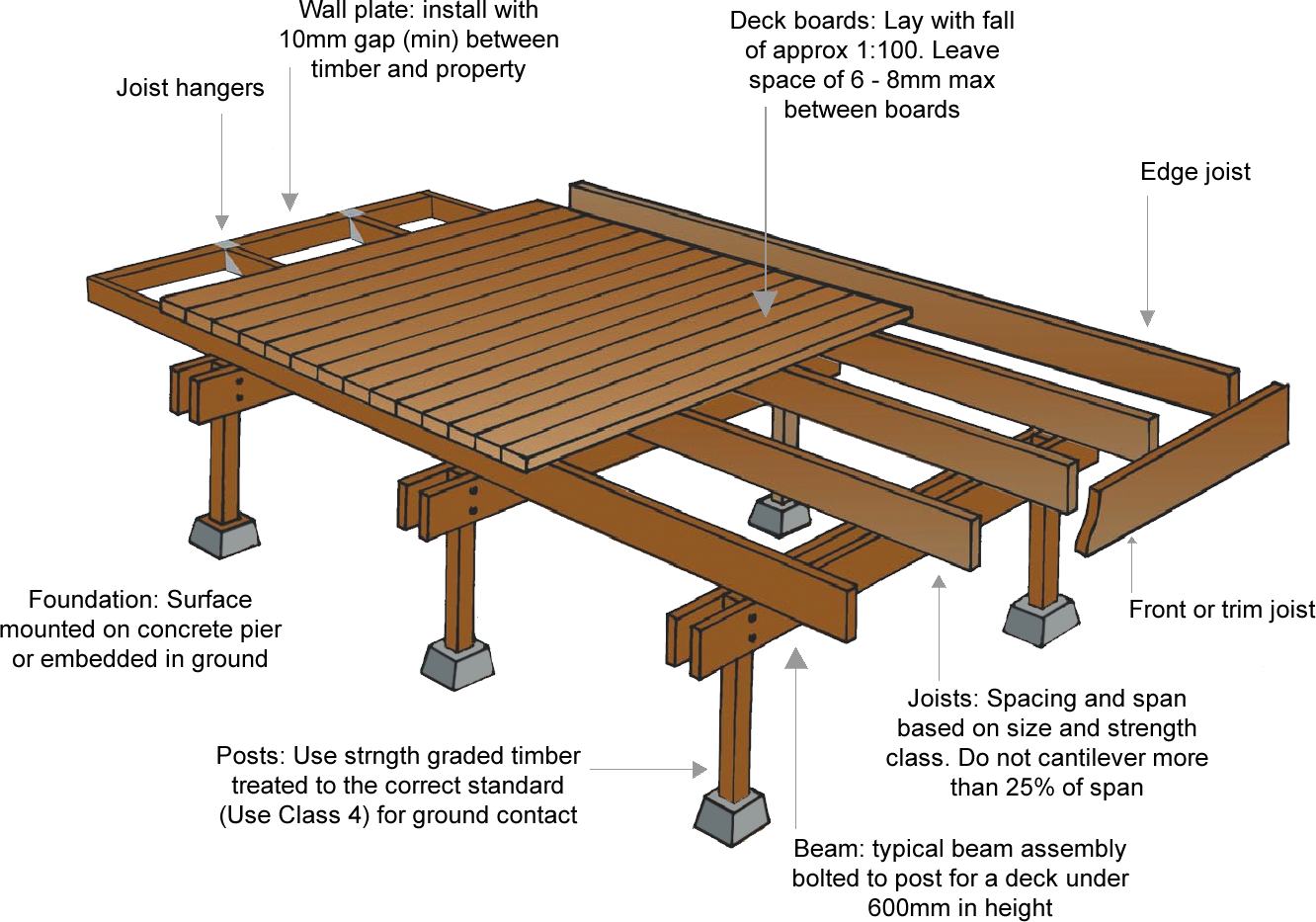

The diagram below shows the basic principles of a post and beam deck construction:

Deck boards are fixed to joists, which are supported by beams attached to posts to create a raised deck

- Wall plates (sometimes called ledger boards) are used to attach decks to a property, leaving a gap of at least 10mm to allow rainwater to drain away freely. Take care not to damage the property’s dpc

- Post, beam and joist spacing varies depending on a number of factors. These include the size of the deck board being used, and the size and strength class of the framing materials. Some typical joist centres and spans are shown in the table for softwood strength class C16

Maximum softwood joist spans (metres - Strength Class C16)

| NOMINAL JOIST SIZE (MM) | DOMESTIC DECKS JOIST CENTRES (MM) | COMMERCIAL DECKS JOIST CENTRES (MM) | ||||

|---|---|---|---|---|---|---|

| 400 | 500 | 600 | 400 | 500 | 600 | |

| 150 x 50 | 3.00 | 2.81 | 2.64 | 2.20 | 1.97 | 1.80 |

| 100 x 50 | 2.00 | 1.86 | 1.75 | 1.47 | 1.33 | 1.22 |

When cross cutting or notching pressure-treated wood on site always brush the cut ends with an end-grain preserver available from your timber supplier. This will ensure the wood continues to be fit for purpose and avoids invalidating any manufacturer’s guarantee.

Laying deck boards

- Build a slight fall into a decked surface for drainage. Lay grooved boards in the direction of fall

- The space between boards should be 5mm to 8mm wide to allow water to drain away and stop dirt accumulating

- Always locate abutting boards over a joist to which a 47mm batten has been attached for support. Fixing points need to be no closer than 25mm from board ends. Pre-drill fixing points to prevent splitting

- Every time the board crosses a joist it should be attached with two fixing points positioned at the quarter points of the board

- Fix grooved boards at the bottom of a groove, ensuring fixings are flush to avoid water retention

- Install hardwood boards using screws, predrilling every fixing point 2mm oversize to allows for any seasonal movement in the wood that could cause screws to break under the tension

- To improve grip, align boards, whether plain or grooved, at a right angle to the primary direction of travel

Parapets or balustrades

For decks raised less than 600mm from the ground, building regulations require parapets or balustrades to be at least 900mm high.

For decks raised more than 600mm, balustrades must be 1100mm high.

Spaces between individual components, like a baluster or rail, should never exceed 100mm.

All newel posts should be capped to avoid water being absorbed into the grain.

Further information and advice

Published by the Timber Decking and Cladding Association

- Technical Bulletin 02 Statutory Regulations

- Technical Bulletin 04 Deck Parapet Design and Installation

- Technical Bulletin 08 Metal Fixings

- Code of Practice 08/01 Raised Timber Decks

Published by TRADA

- Timber Decking, by Patrick Hislop

Available on www.woodcampus.co.uk:

- Deck design and installation (online learning)

- Many other videos and publications

Sustainable timber

Timber is the most sustainable mainstream building product. It is naturally renewable. Over 90% of timber used in UK construction comes from Europe, where more trees are grown than harvested (source: TTF Statistical Review 2016).

Softwood and temperate hardwood forests in Scandinavia, Europe, Canada and North America are stable or growing. Growing forests act as carbon sinks; wood products act as carbon stores.

Ask for PEFC or FSC Chain of Custody certification.