Strength Grading

TOPIC CHECKLIST

- Does the project need strength-graded timber?

- Do you know enough about grade-marking to be sure you’ve got the right timber?

- Store strength-graded timber in a dry and well-ventilated area away from direct heat sources.

Visual strength grading

Visual strength grading uses the grader’s experience to assess each piece of timber according to rules that define the size, type and number of strength-reducing characteristics

allowed in each grade.

Natural strength-reducing features include knots, wane (the uneven edge caused by a residue of bark) and the slope of the grain. Other strength-reducing features, such as splits or shakes (the splitting of the wood fibres along the grain) may have developed as a result of drying.

The grader assesses each piece and stamps it with the appropriate mark.

Machine strength grading

Machine grading is based on the relationship between strength and stiffness, and is best suited to high volumes of timber of similar species and cross section.

The machine grades each piece and stamps it with the appropriate mark.

The rules governing strength grading of timber are prescribed in British and European standards.

BS EN 14081:2005 covers visual and machine grading of structural timber.

It refers to BS 4978:2007+A1:2011 for softwood visual grading rules and BS 5756:2007+A1:2011 for hardwood visual grading rules.

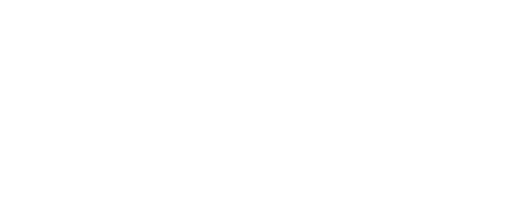

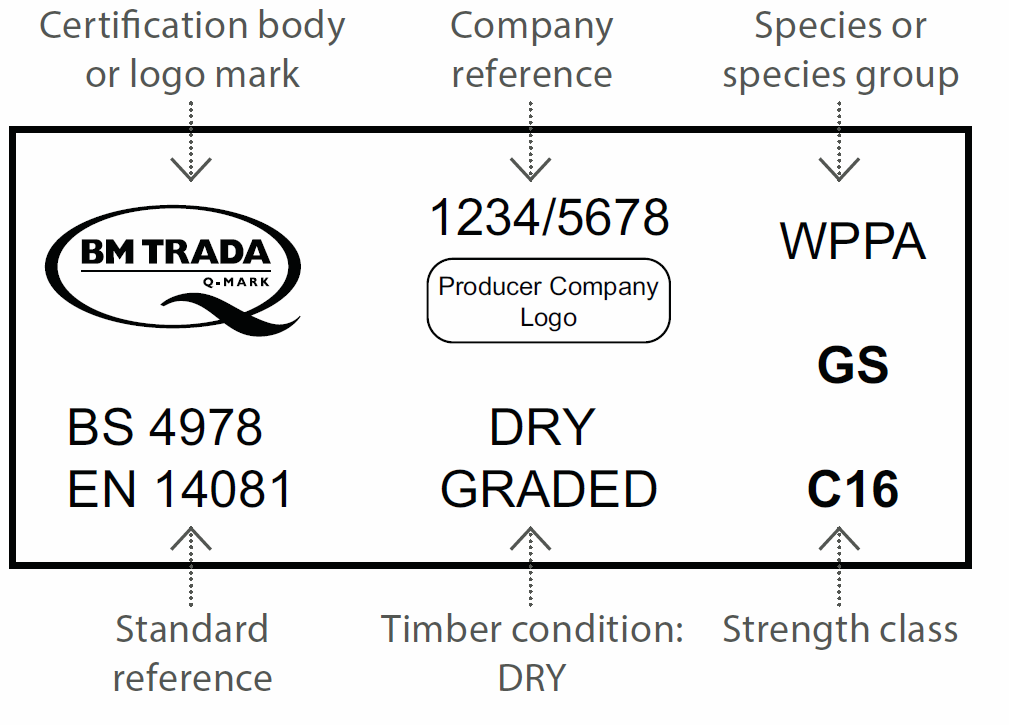

Understanding the grade mark

Timber marked DRY is graded at a maximum moisture content of 20% and should be transported, stored and installed in the building in a manner that does not allow this moisture content to be exceeded.

Although moisture content of 20% or less is permissible for internal use, further shrinkage is likely as the timber dries in service. For example, timber joists used in intermediate floors may dry to around 12% moisture content.

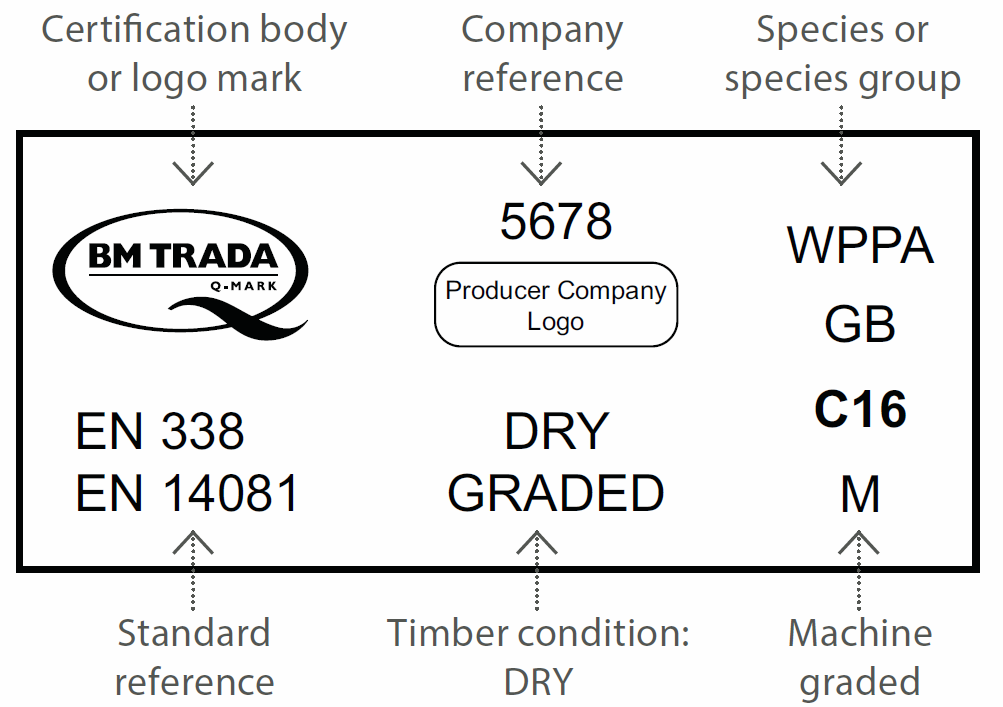

The species is shown on the grading stamp by a code such as WPPA (European redwood/pine or whitewood/spruce) or WPNN (British Corsican/Scots pine). GS (General Structural) and SS (Special Structural) are the visual grades of the timber. A supplier’s stamp might look like this:

The chain of custody (COC) number demonstrates the timber is from a legal and sustainable source. North American graded timber is accepted in Europe under BS EN 14081 and may be marked J&P (joist and plank grade)or NAMSR (North American machine stress-rated lumber).

Strength grades

The strength of a piece of timber depends on a combination of the strength of the timber species and the grade of the individual piece. A high grade of timber from a weaker species may be just as strong as a low grade of timber from a strong species.

To make specifying easier, species and grades are grouped into strength classes of similar strength for softwoods and hardwoods. In both cases, higher numbers indicate stronger timber:

The most common strength classes for softwoods are C16 and C24. TR26 is a class specific to trussed rafters.

Hardwoods range from D18 to D70.

The table overleaf shows some species and grades commonly used in UK construction are grouped into strength classes.

| SOURCES AND SPECIES | GRADING RULES | STRENGTH CLASSES | |||||

|---|---|---|---|---|---|---|---|

| C14 | C16 | C18 | C22 | C24 | TR26 | ||

| European redwood/whitewood (pine/spruce) | BS 4978 visual | GS | SS | ||||

| BS EN 14081 parts 1-4 machine | ⚫ | ⚫ | ⚫ | ||||

| British pine | BS 4978 visual | GS | SS | ||||

| BS EN 14081 parts 1-4 machine | ⚫ | ⚫ | ⚫ | ||||

| British spruce | BS 4978 visual | GS | SS | ||||

| BS EN 14081 parts 1-4 machine | ⚫ | ⚫ | |||||

| British Douglas fir | BS 4978 visual | GS | SS | ||||

| British larch | BS 4978 visual | GS | SS |

Sustainable timber

Timber is the most sustainable mainstream building product. It is naturally renewable. Over 90% of timber used in UK construction comes from Europe, where more trees are grown than harvested (source: TTF Statistical Review 2016).

Softwood and temperate hardwood forests in Scandinavia, Europe, Canada and North America are stable or growing. Growing forests act as carbon sinks; wood products act as carbon stores.

Ask for PEFC or FSC Chain of Custody certification.

See Wood Campus RIBA CPD module Procuring Sustainable Timber for more on timber certification and sustainability and government requirements.